Software

TTGraph Software

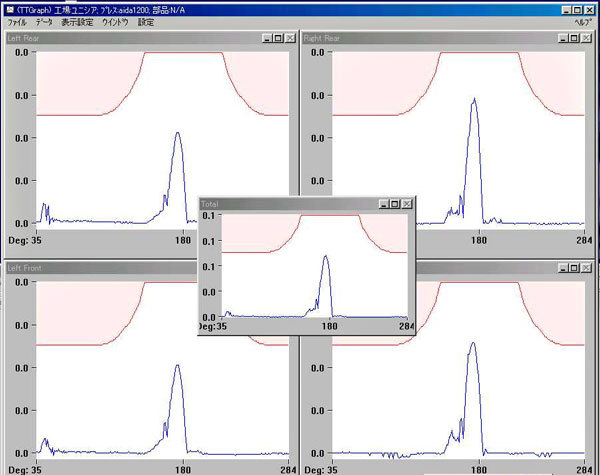

Waveform analysis with TTGraph software for windows computer.

If you use the optional waveform analysis software TTGraph, the one-shot waveform for each operation mode is displayed on the display of the personal computer.

By grasping the processing load with numerical values and waveforms, it becomes possible to manage and monitor the processing process with the optimum load in the good product state.

It also contributes to grasping wear and abnormality of the mold and dramatically improving die life.

TT Graph is a signature analysis program that generates tonnage signatures and provides a simple approach for analyzing the signatures. Tonnage signatures provide a graphical picture of what is happening during the press stroke. The signatures can be resolver or time-based, depending on the type of monitor being used.

TT-Graph tonnage signatures help identify press and die problems such as:

- Off center loading

- Loose tie rods

- Gib chatter

- Loss of binder tonnage

- Die timing

- Worn weld beads

- Dull punches

- Bearing problems

- Nitrogen cushion wear

- Lubrication variances

Signatures:

Signatures can be stored, recalled and overlaid with new signatures for comparison. Variances in the signature indicate potential mechanical press problems, die problems and subsequently off tolerance parts. When an alarm occurs, signatures are automatically saved when also using PressNet. This eliminates the worry of someone having to save it. Once it is saved, someone can look at it to pinpoint the problem and refer to it in the future if the same problem occurs.

Enveloping:

Enveloping puts high and low tonnage limits around the actual tonnage signature throughout the entire press stroke. TT Graph can graphically show this for the N260 Series Production Monitors and SLIM. If the tonnage increases or decreases and either of the high or low limits are violated, an alarm occurs and the press will stop if you are using enveloping with these monitors. The limits are typically used more for die protection and part quality assurance than just press protection. A high enveloping fault may indicate slug buildup, material misfeed, etc. A low enveloping fault may signify a loss of nitrogen cylinder pressure, die wear, not enough shear on a punch, etc.

▼Products Line

SafetyDevices AreaSensor

DSP-J

Laser Safety Device for PressBrake

Admiral AX

Light Curtain Safety Device

EOS series

LB100

Laser Safety Device

for Press Brake

Pull-out

Safety Device

Press Accesory

KBM-4

Brake Stop Timer

Scrap Shooter

SM series

Profence/safety Fence

Brock Guard/ Alminum Fence

Safety Hand Tool

Safety Press Switch

Parts for Pull out

safety device

LoadMonitor

LoadMonitor

N800

LoadMonitor

N500

LoadMonitor

N700

LoadMonitor

TTLM

LoadCell・AutoCell

LoadSensor

T400

Softwear

for Load Monitor

LoadMonitor

Comparison

Movie