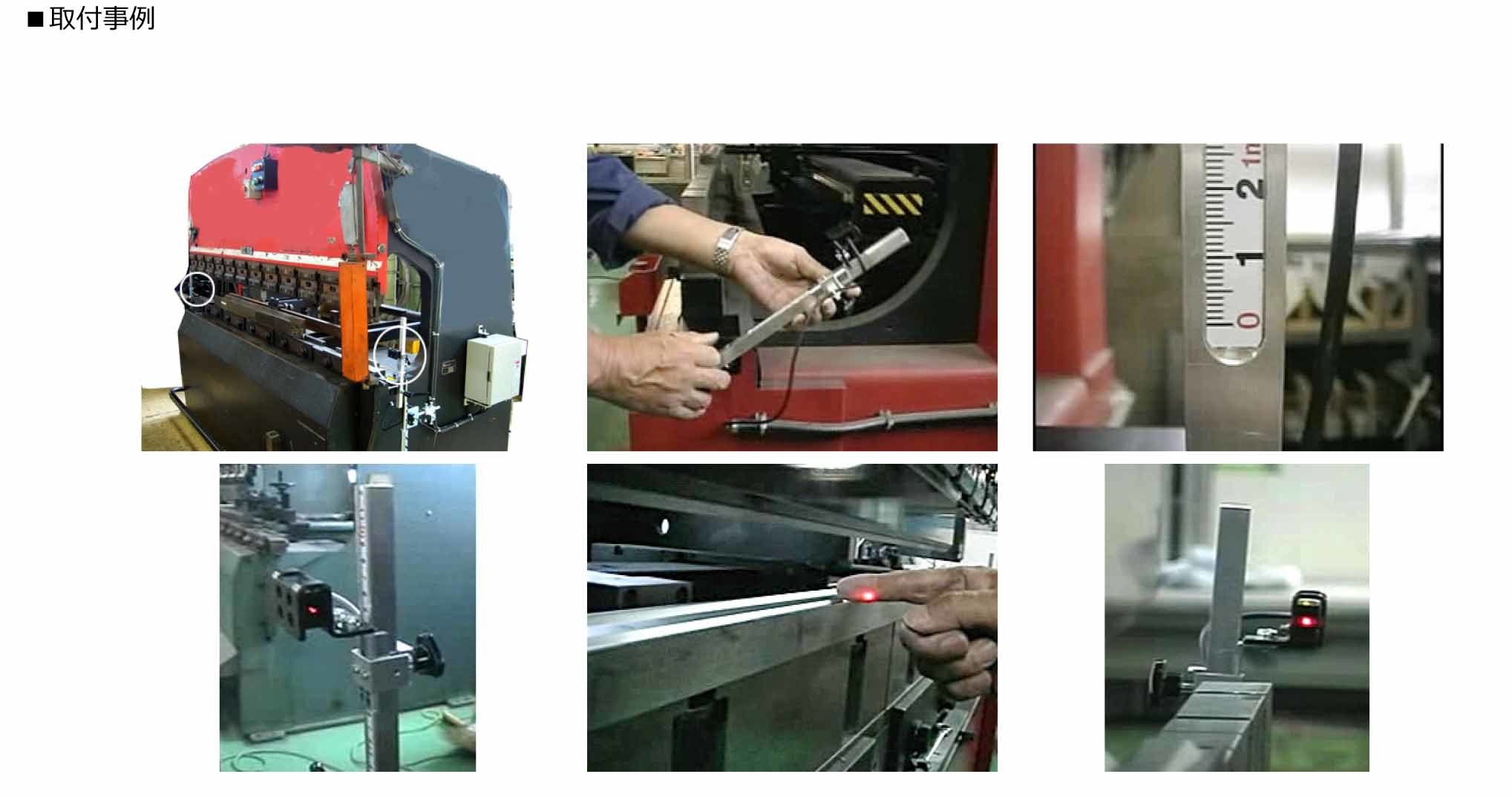

LB100 Safety Equipment for pressbrake

Features

- 1.It is outstandingly effective as a safety measure when a hand or a finger approaches within the danger limit and the material must be protected and processed.

- 2.Many companies are starting to use it as a laser safe guard for press brakes.

- 3.We are getting feedbacks such as “It is really easy to use and you can work with confidence.”

- 4.The safety devices before had bad workability and often had problems. By installing the laser safe guard for press brake the dangerous area decreased greatly than before.

- 5.Laser beam detects 2mm objects.

- 6.Even if a material enters, it wouldn’t stop the machine from processing. Also small items can also be processed. Easy sensor positioning.

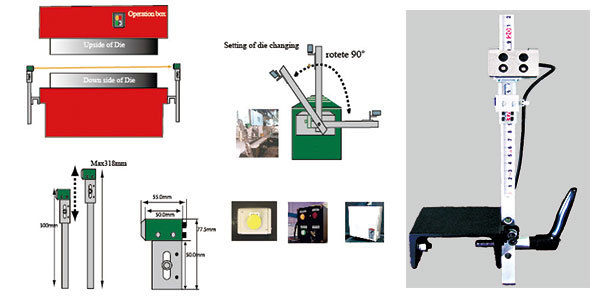

- 7.During mold exchange, since it can be moved with a single touch, there is no difficulty in exchanging.

- 8.LB100 is a laser safe guard. It is not a safety device that has certification.

Outline

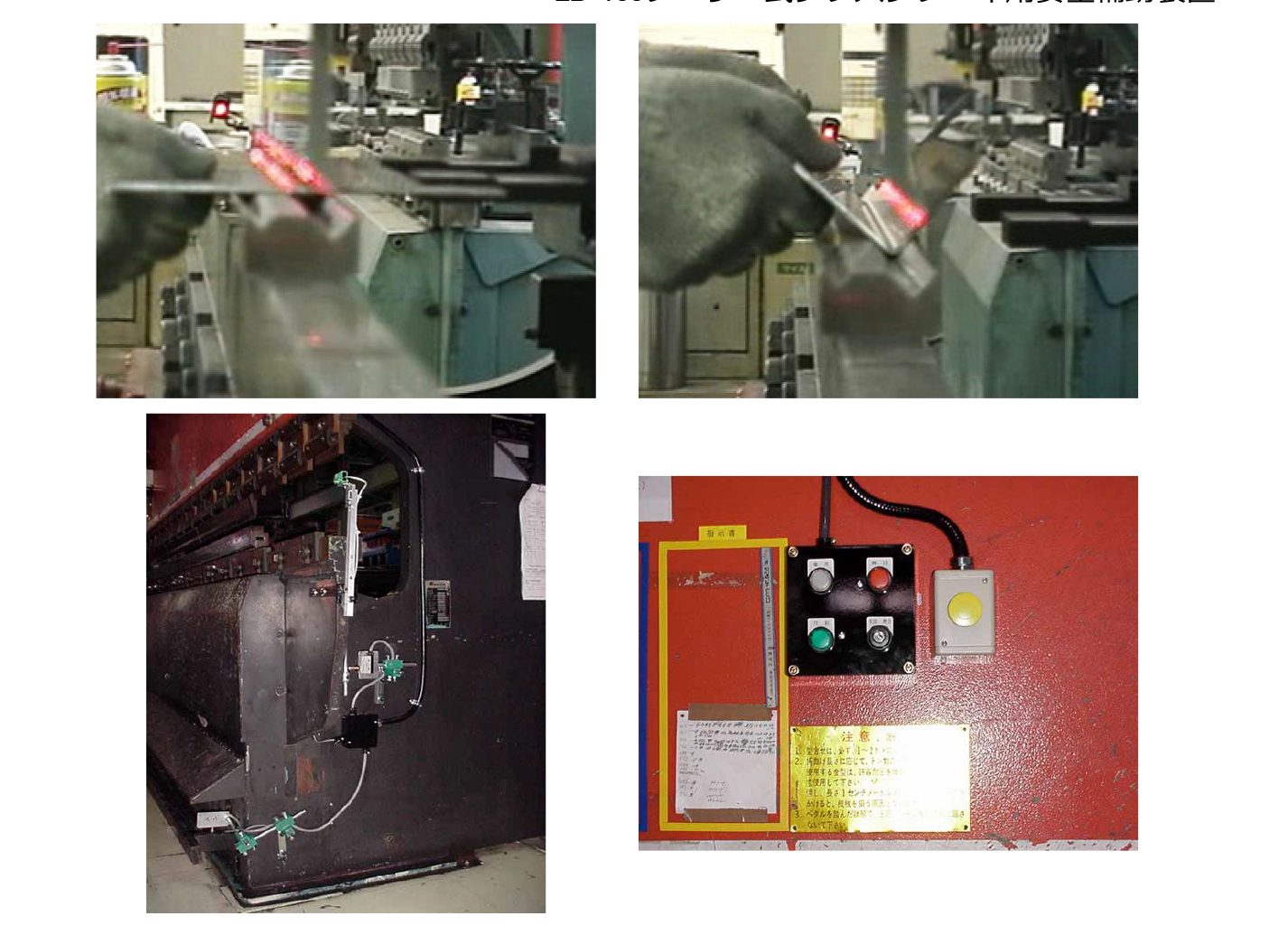

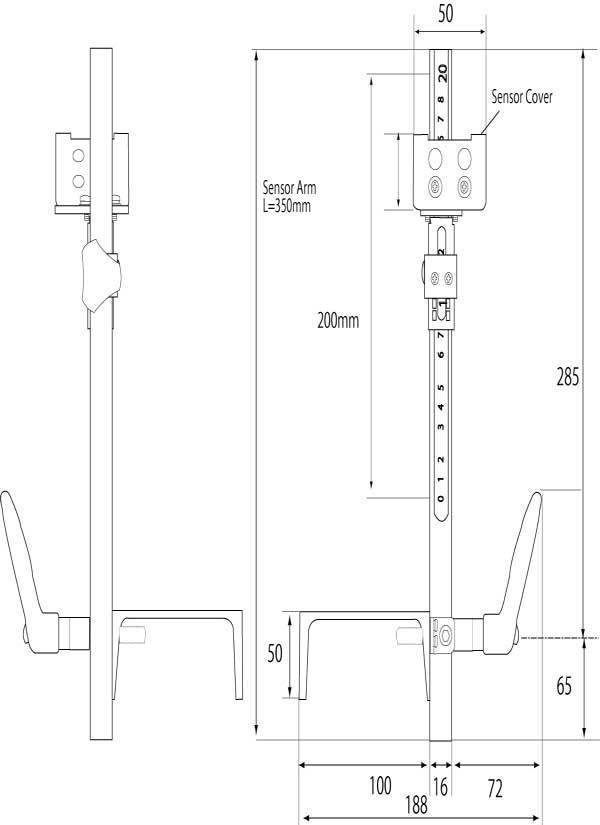

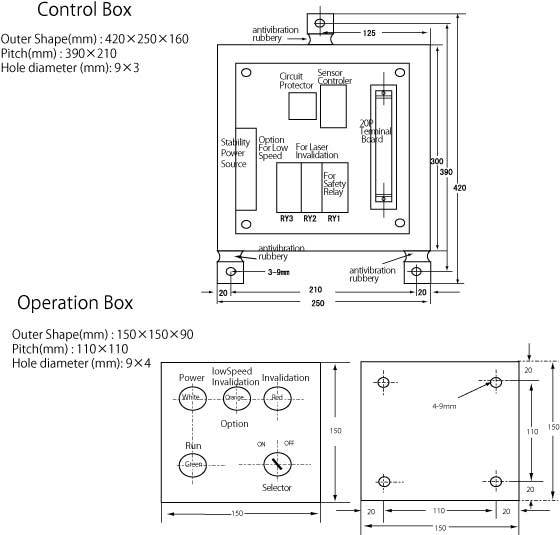

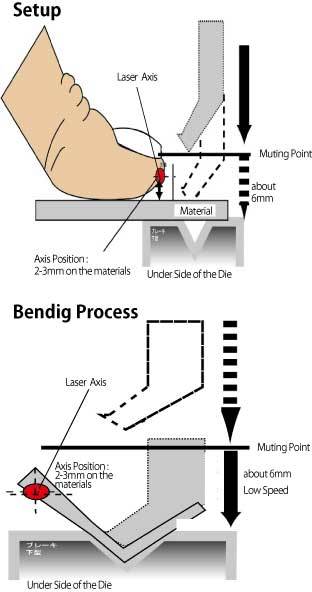

The laser safe guard for press brake LB-100 detects a finger by laser beam of one optical axis. The laser beam emitted from the emitter is received by the receiver. By shielding the laser beam between the emitter and the receiver, the safety relay in the control box operates. By connecting the output signal of the safety relay to the stop circuit of the press brake, the slide of the press brake will stop suddenly. However, the function of the press brake actually stops the slide.

Please set the optical axis of the laser beam 2~3mm (front side) from the upper part of the material.

In the case of a hydraulic type, the press brake slide stops when the laser beam is shielded from high-speed descent.

When the slide of the press brake comes down at a very low speed and the space becomes less than 6mm, the laser beam becomes invalid so even if the laser beam is shielded, the slide does not stop so the bending can be processed.

Also, when the slide is raising, the slide does not stop even if the laser beam is shielded.

( It depends on the hydraulic circuit, so please contact us. In the case of mechanical type, detect setting will be made by the angle)

As an option, you can install a beam bypass circuit.

When the beam bypass circuit stops suddenly at high speed descent, by pressing the operation preparation button (option) in the operation preparation box, it will be released.

Setup:

Set laser axis 2-3mm above the surface of the materials.

Muting:

Set muting position by Press Brake machine.

By interrupting the beam between Sender and Receiver,Safety Relay in the Control-box outputs the signal to the Stop cuircuit in the Press Brake.

Laser detection system begins to mute at muting position.

You can bend materials or do smooth operation even if it interrupt laser beam.

*Motion is different by Hydraulic circuit,

Reset:

Optional Beam Bypus Circuit system is ready.

If Slide stops by interrupting the beam during high Speed position,it is easy to release press stop system by pushing Reset button on the Reset Box.

Laser beam detects objects(0.5mm) It is able to process smallest pieces which must be led by fingers for bending

Specification

| specification | |

| Detection distance | 15m |

| Response Time | 20ms |

| Minimum detection object | Opaque body of 2mm or more |

| Laser beam | 0.5ms 100mA(DC30V)Max Red semiconductor laser 650nm |

| Input power supply | AC100V-200V |

| System response time | 20m sec |

| Safety standard | class 2 |

| Output relay | 6A max |

| Laser output rating | sink current 100mA 8DC30V)MAX |

| system switching method | Enable/Disable switch |

| Power supply for emitter | Red semiconductor laser |

▼Products Line

SafetyDevices AreaSensor

DSP-J

Laser Safety Device for PressBrake

Admiral AX

Light Curtain Safety Device

EOS series

Pull-out

Safety Device

Press Accesory

KBM-4

Brake Stop Timer

Scrap Shooter

SM series

Profence/safety Fence

Block Guard/ Aluminum Fence

Safety Hand Tool

Safety Press Switch

Parts for Pull out

safety device

LoadMonitor

LoadMonitor

N800

LoadMonitor

N500

LoadMonitor

N700

LoadMonitor

TTLM

LoadCell・AutoCell

LoadSensor

T400

Softwear

for Load Monitor

LoadMonitor

Comparison

Movie